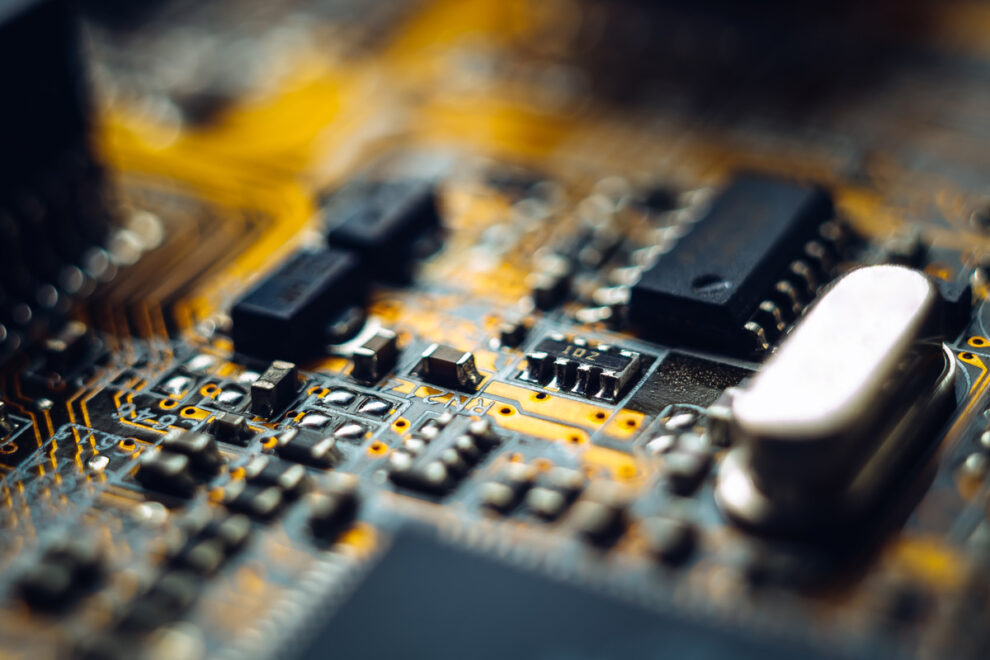

For the electrical and electronics industry, our services improve the electrical conductivity and corrosion protection of components.

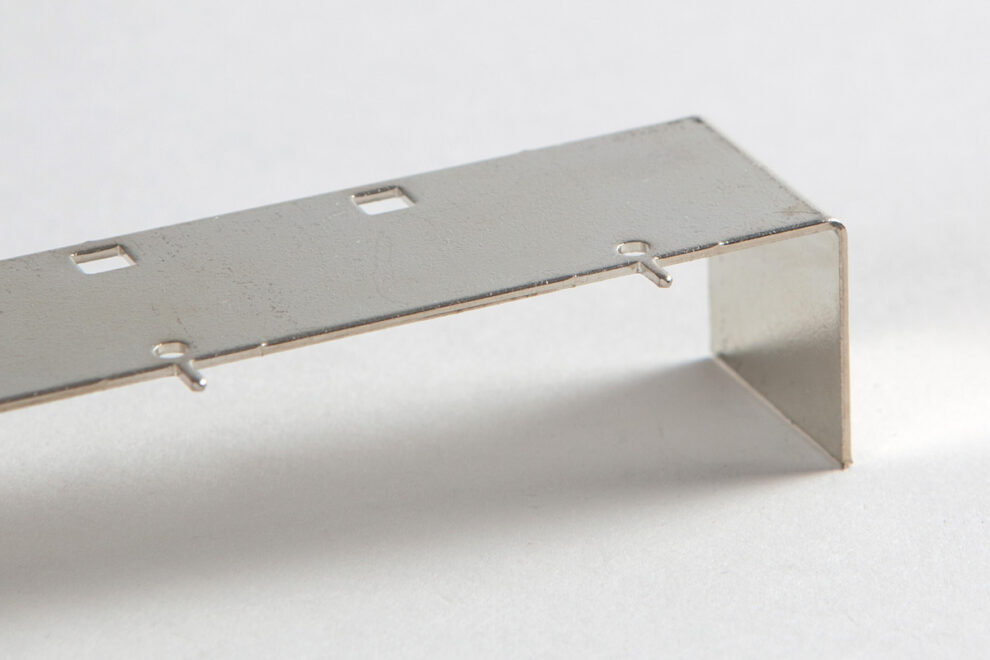

We produce contact surfaces for various parts, corrosion protection for power rails, passivation or anodising of aluminium enclosures, corrosion protection for equipment frame structures, and anodising of signs and equipment front panels prior to laser or tampo marking. We do both drum and hanging tin plating of contact parts. For brass parts, a copper or nickel interlayer ensures a clean appearance for the tin coating over longer storage periods. Passivation or electroless nickel plating of aluminium housings provides uniform corrosion protection on all surfaces of the part, including to a limited extent internal threads to ensure ground contact. All our treatments are RoHS compliant and do not contain hexavalent chromium. The metals we use are from reliable audited suppliers and conflict-free regions.